State-of-the-art technologies for sustainable fish farming – our solutions

↓

Perfection all round – RAS systems with closed-loop circuits

Can you breed fresh fish without polluting our seas, lakes and rivers and without using growth-enhancing substances? The clear answer is: Yes, you can! Innovative RAS facilities (Recirculating Aquaculture Systems) make sustainable breeding possible. This will ensure that the next generation can continue to enjoy fresh fish by making the best use of energy and natural resources and minimising environmental impact.

Source: FTN AquaArt AG

“Circular economy is the future. It uses resources more efficiently, creates value in local areas, provides opportunities for new business models and strengthens economic resilience.”

Clean, safe, scalable - the key benefits of aquaculture systems

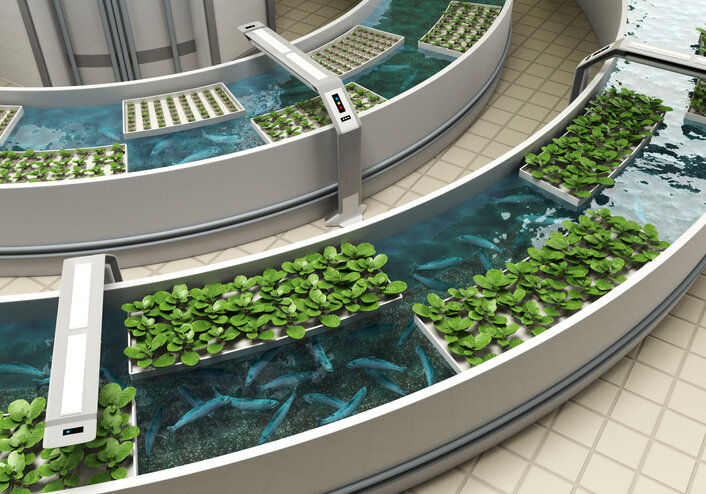

1. Closed aquaculture systems

RAS technology (Recirculating Aquaculture Systems) is based on closed water circuits and therefore enables land-based breeding methods. Water tanks are connected to complex filter systems that ensure a mechanical-biological water treatment. The facilities can be adjusted to the reflect the unique needs of each fish species raised.

2. Clean water

By using state-of-the-art filtration and oxygen enrichment systems, targeted oxidation processes and UV disinfection, 98 per cent of the water in FTN AquaArt AG RAS facilities is reused. As we can also ensure that the water is free of pathogens at all times, antibiotics and pesticides are not required.

3. Maximum resource efficiency

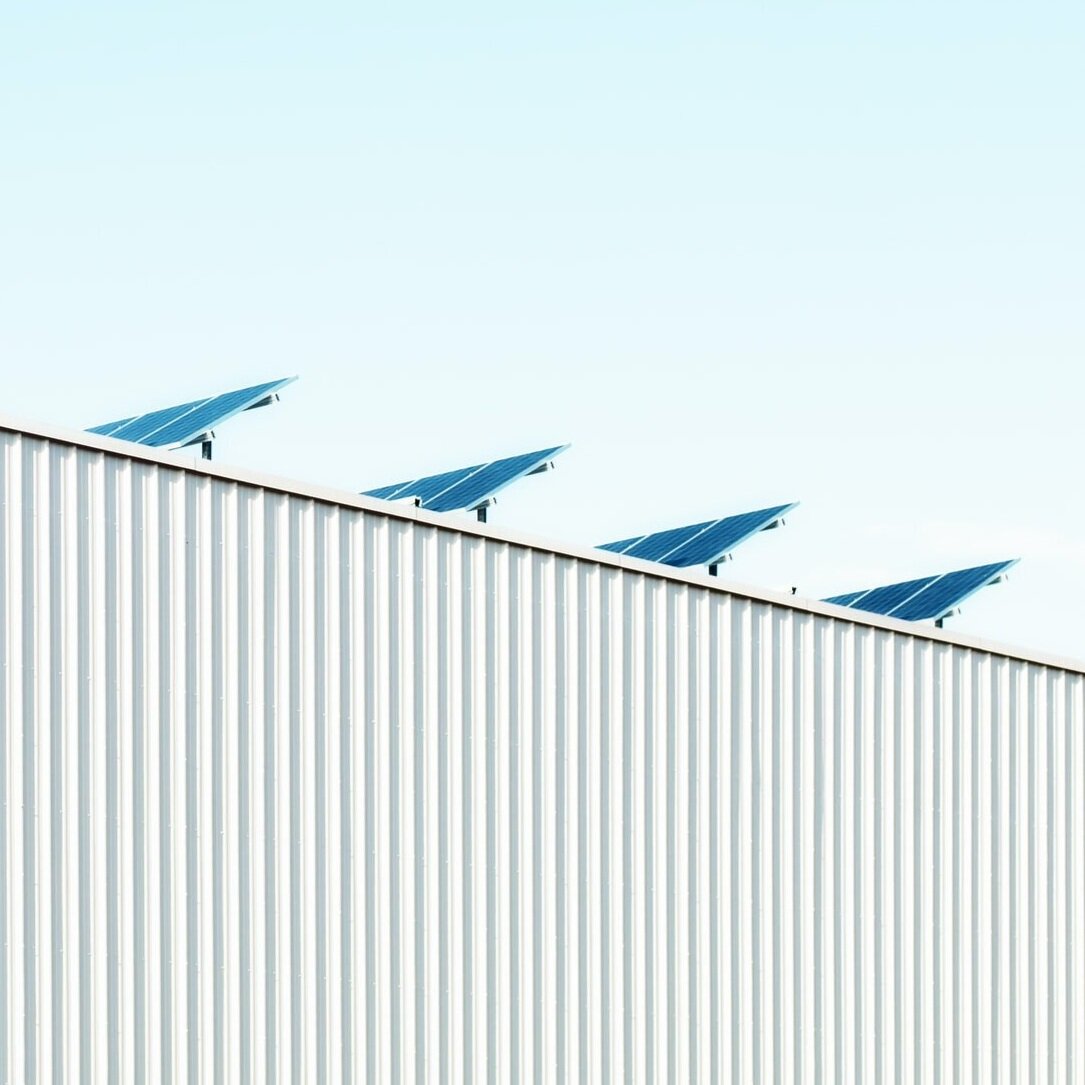

We’re committed to ensuring maximum energy efficiency and the use of renewable energy sources (e.g., photovoltaics, heat pumps, waste heat from industrial operations). By using innovative technology, we can guarantee an optimal cost-benefit ratio for every fish raised. Our use of by-products is another way we break new ground. Slaughter remains can be converted into animal feed and biogas, while wastewater and fertiliser surpluses can be used in agriculture. The CO2 produced can also be used in greenhouses, aquaponics and vertical farming.

4. Intelligent measurement systems

Our proprietary measurement technology makes it easy to operate FTN facilities. Our systems control the entire fish and energy technology, oversee the management of stock fish and keep you updated about the most relevant parameters through messages on the digital device of your choice. This means maximum production security, low operating costs and minimum energy and water usage.

5. Scalable solutions

Our RAS systems can be set up anywhere, irrespective of climate and geography. Your facility can be adjusted to reflect local demand and extended as required. Each model is designed as an independent production unit with all biologically relevant functions – allowing you to extend your fish farm flexibly over time.

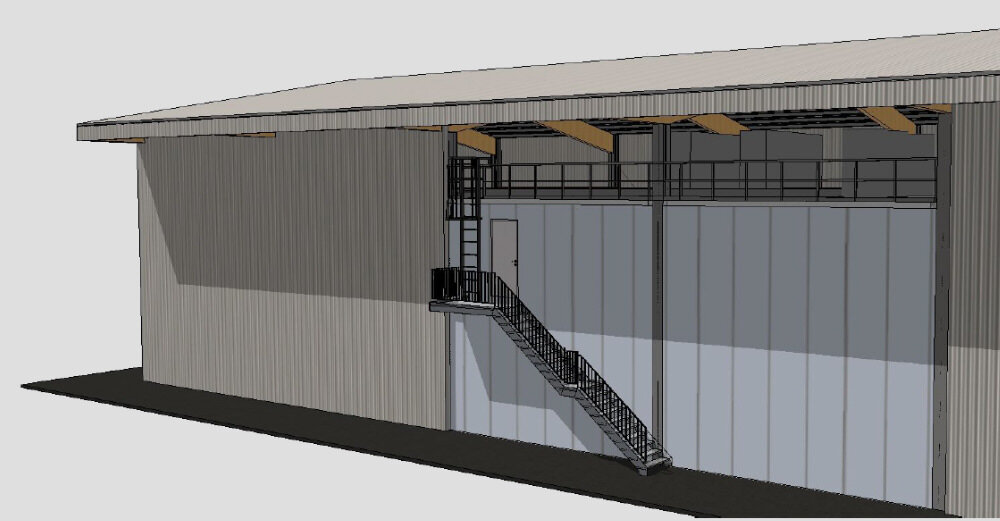

Benefit from our expertise and experience - facility design and construction

FTN is a pioneer for indoor aquaculture. 30 years' experience at the Müritz fish farm as well as numerous international projects have allowed us to acquire in-depth knowledge on fishery biology and engineering.

We’re only too happy to share this expertise with our clients and ensure that you’re supported every step of the way – from planning and facility construction right through to its successful operation. This doesn’t only mean setting up an aquaculture system that is perfectly tailored to your location and desired fish species. Thanks to the most innovative automation technology, resource-saving energy management and proven Swiss engineering skills, our systems are also easy and efficient to operate.

We provide ongoing and seamless support – from planning to operations

1

Analysis and project definition

Defining goals and challenges, compiling well-established and resilient feasibility studies

⭣

2

Conception and planning

Technical implementation planning, obtaining all permits and identifying the right fish species for your facility

⭣

3

Construction and implementation

Facility and system set-up, initial fish stocking

⭣

4

Support and maintenance

Servicing and supporting the facility, training staff, integrating systems and technologies

⭣

5

Education and training

On-the-job training for operating staff, coaching decision-makers, student internships

For the highest possible operational safety - our control system

Our unique control system makes our facilities very simple to operate. It measures, monitors and controls all relevant fish parameters and the building technology itself. Stock management is also integrated directly into the system. Any variations from the target value will trigger an alert on the digital device of your choice (smartphone, tablet, desktop). The internally developed system ensures maximum production reliability, lower operating costs and minimum energy and water usage. Clients can also operate the system remotely, ensuring the best possible operational safety and optimal monitoring of your fish farm.

A brief best-of of FTN – our clients and projects

Localfish Lyss

Place: Lyss, Switzerland

Client:

Seeland Fish

Realization: 2019

Annual production:

approx. 40t of edible fish

Fish species: Egli

Fenaco Genossenschaft

Place: Büron, Switzerland

Client:

fenacoGenossenschaft

Realization: 2016/17

Annual production:

approx. 10t of edible fish

Species: Pike perch

Bern University of Applied Sciences HAFL

Place: Zollikofen, Switzerland

Client:

BFH-HAFL

Realization: 2021

Annual production:

Research facility

Fish species: Various

Kenzenau fish

Place: Schweizersholz, Switzerland

Client:

KenzenauFisch AG

Realisation: 2021/22

Annual production:

approx. 40t of edible fish

Fish species: Pikeperch / Catfish

FTN

Hatchery Rafz

Place: Rafz, Switzerland

Client:

FTN AquaArt AG

Realisation: 2020

Annual production:

approx. 2 million stocked fish

Fish species: perch / zander

Localfish Rafz

Place: Rafz, Switzerland

Client:

Localfish AG

Realisation: 2022/23

Annual production:

approx. 220t of edible fish

Fish species: perch / zander

FTN

Hatchery Lauchringen

Place: Lauchringen, Germany

Client:

FTN AquaArt AG

Realization: 2023/24

Annual production:

approx. 2 million stocked fish

Species: Pike perch

Localfish Lauchringen

Place: Lauchringen, Germany

Client:

FTN AquaArt AG / Localfish AG

Realization: 2024/25

Annual production:

approx. 400t of edible fish

Fish species: Pike perch

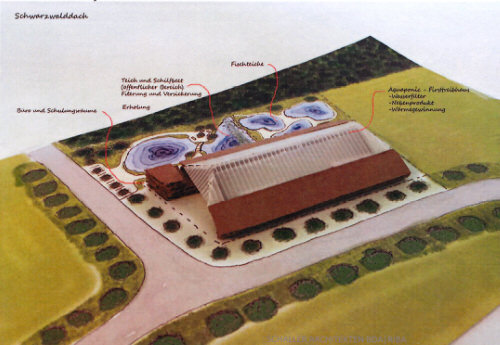

New opportunities in agriculture –circular economy

Regenerative agriculture, vertical farming and aquaponics all have one thing in common – they’re based on regenerative cycles and open up new opportunities for sustainable food production. FTN systems incorporate all three essential aspects of the closed-loop economy. The technical requirements governing filter systems and control technology. Efficient resource management with closed energy and material cycles. And the biological cycles in fish farming, water management and hydroponics. Our vision for the future is the development of holistic, sustainable ecosystems:

Aquaponics – fish farming and cultivation of crops through hydroponics

Vertical farming - the production of plant and animal products in multi-storey buildings

Urban Farming - food production in urban areas for local and regional consumption.